By Anca Gagiuc on April 22, 2014 in Technology

Giant 3D printers, though still in the research stage, m ay be the perfect candidate to replace built-by-hand homes.

ay be the perfect candidate to replace built-by-hand homes.

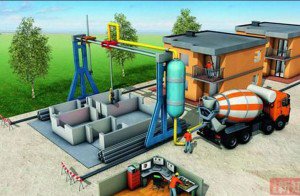

USC Professor Behrokh Khoshnevis designed a robot able to build a 2,500-square-foot home in just 24 hours. The process, called Contour Crafting, is in fact scaling up 3D printing to the scale of the building. The big robot’s actions are dictated by a computer program: the construction site is cleared and leveled; the workers lay down two rails a few feet further apart than the building’s width and a computer-controlled contour crafter takes over from there. A gantry-type crane with a hanging nozzle squirts out concrete and with a components-placing arm travels along the rails. The nozzle lays layers of concrete creating hollow walls, and fills them in with additional concrete. People would only install doors and windows. The animation here gives a pretty good idea of how it would ultimately work.

“It’s a CAD/CAM solution,” says Khoshnevis. The buildings are “designed on computer and built by a computer”. This method has proved to produce much stronger structures than traditional building methods. According to Contour Crafting, the tested wall is a 10,000PSI (pounds per square inch) strength compared to the average 3,000PSI of a regular wall.

With the Contour Crafting solution the cost of home-owning could be slashed, making it possible for millions more humans – especially in developing countries – to have houses. The first thing that comes to mind is the opportunity to build emergency and replacement housing in disaster relief areas, such as recovery from typhoons and hurricanes. It could also be used to build high-quality shelter for those living in desperate conditions: at the beginning of the 21st century, there are almost one billion people in need of stable housing around the world.

With the Contour Crafting solution the cost of home-owning could be slashed, making it possible for millions more humans – especially in developing countries – to have houses. The first thing that comes to mind is the opportunity to build emergency and replacement housing in disaster relief areas, such as recovery from typhoons and hurricanes. It could also be used to build high-quality shelter for those living in desperate conditions: at the beginning of the 21st century, there are almost one billion people in need of stable housing around the world.

The goal of Contour Crafting is to build communities at just a fraction of the cost, of the time, in less jeopardy, and with a higher architectural flexibility. Thanks to technology, endless templates can be designed to create different styles of houses, enhancing creativity up to levels impossible to achieve so far, without overwhelming costs. It could even be used to build large commercial buildings: “You can have multi-nozzle machines and even have the structure climb the building,” says Khoshnevis.

Probably one of the biggest concerns on the subject is reflected in the effect this technology could have on builders and construction jobs. Building and construction has remained one of the very few industries not conquered by the construction line automation, remaining one solid employment source worldwide. According to the International Labor Organization, the construction industry employs nearly 110 million, playing a major role in combating unemployment and in taking in surplus labor from rural areas.

However, this is not a first in the history of industrialization: in 1900 nearly 62 percent of Americans were farmers, whereas today, less than 1.5 percent are in agriculture today,. The reality is that plenty of new jobs can be created in this sector as well. Furthermore, construction is much more dangerous than agriculture or mining, killing 10,000 people every year.

The giant robot is still in research, currently funded by NASA and the Cal-Earth Institute. The space agency is investigating the possibility to construct modern civil structures, on Earth and on the Moon. “This technology is like a rock that we have rolled to the top of a cliff,” Khoshnevis told Discover Magazine, “just one little push and the idea will roll along on its own.”

Photos courtesy of Contour Crafting & NASA.